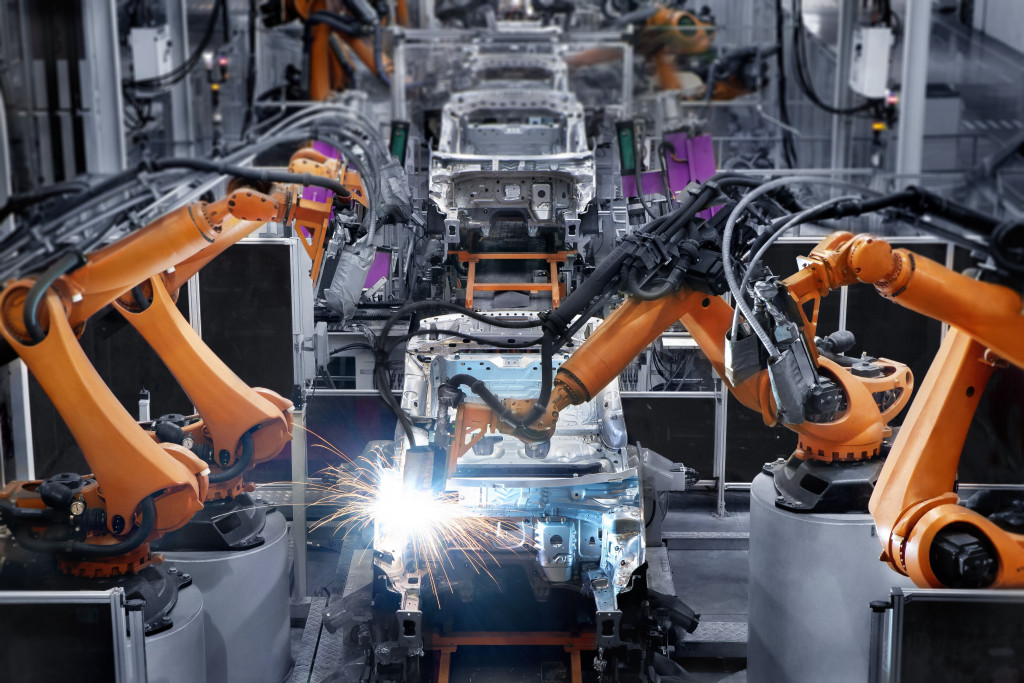

Companies must invest in heavy-duty manufacturing equipment to remain competitive in the manufacturing industry. Not only does this equipment help a company maintain its productivity levels, but it can also help reduce costs and improve product quality.

Manufacturing companies have to protect their equipment at all costs, as it is a critical part of their business. To keep the equipment running properly, companies need to have a plan in place for how to protect it from damage or theft. It can involve spending time, effort, and money on security measures, such as installing cameras and alarms, hiring security guards, and ensuring the equipment is well-maintained. It might be a costly venture, but it will be worth it if you can make the most out of those machines. Here are a few more tips to help you protect those valuable assets.

Keep Track of Assets

Heavy equipment is a valuable asset for any manufacturing company. It’s essential to keep track of this equipment through documentation and asset tracking software to prevent theft and misplacement. Without good documentation, it can be challenging to determine where heavy equipment is stored and who is responsible for it, leading to misplaced or stolen equipment, which can be costly for the company.

Asset tracking software can help keep track of heavy equipment by recording the location of each piece of equipment. Companies can access this information from any computer or mobile device, so you can always know where your equipment resides. You can rest assured that your heavy equipment is safe and accounted for by using asset tracking software.

Create Security Measures

Companies need to set and enforce security measures to ensure that their manufacturing equipment remains safe. Without security measures in place, it would be easy for someone to steal or damage the equipment, significantly impacting the company’s operations.

Companies should consider installing cameras and alarms to protect their equipment. Security guards can also provide protection, as can well-maintained equipment. Companies can help ensure that their manufacturing equipment remains safe and productive by taking these precautions.

Prevent Wear-and-Tear

Manufacturing equipment is often subject to wear and tear, quickly deteriorating. It can lead to decreased productivity and increased costs for the company. Preventing wear-and-tear on manufacturing equipment is vital for running correctly and ensuring that it lasts long.

One way to prevent wear and tear on manufacturing equipment is to protect it from paint overspray. Paint overspray can cause damage to the equipment, leading to rust, corrosion, and other problems. Companies can install paint overspray protection products to protect the equipment from paint overspray. These products help keep the paint from hitting the equipment, preventing damage.

Another way to prevent wear and tear on manufacturing equipment is to keep it clean. Dust, dirt, and other debris can cause the equipment to wear down prematurely. Companies can use various cleaning products to keep the equipment clean, such as solvents, degreasers, and disinfectants. Cleaning the equipment can help prevent any damage and keep it running smoothly.

Conduct Regular Maintenance Inspection

Companies need to conduct regular maintenance inspections on their manufacturing equipment. The step will help identify potential problems and fix them before they become too serious. It can also help increase the life of the equipment and prevent downtime.

A qualified team of technicians should conduct regular maintenance inspections. The team should be able to fix any identified problems during the inspection. They should also be able to provide preventive maintenance, which can help reduce the likelihood of future problems.

Hiring a qualified team of technicians to conduct regular maintenance inspections on your manufacturing equipment is crucial to running smoothly and efficiently.

Set Aside Funds for Replacement

A manufacturing company needs to quickly set aside cash to replace broken or misplaced manufacturing equipment. It will help keep the company running smoothly and avoid any downtime. Delays and disruptions can lead to financial losses, making it necessary to seek suppliers as soon as machines show signs of defect.

Companies can set aside money to replace their manufacturing equipment by creating a budget. The funding can help you purchase new equipment when necessary or to repair existing equipment.

Another way to set aside money for replacement is through insurance. Companies can purchase insurance policies to help cover replacing damaged or lost equipment. It can be a helpful way to ensure that the company has the funds necessary to replace damaged or misplaced equipment.

A manufacturing company needs to plan to replace broken or misplaced manufacturing equipment quickly. It will help keep the company running smoothly and avoid any downtime. By setting aside money to replace the equipment, either through a budget or insurance, you can prepare the company for any situation.

Companies that can take care of their manufacturing equipment can ensure its longevity and reduce the need for replacements. By investing in this measure, you’ll be protecting your investment by ensuring it lasts long.