- Warehouse storage is crucial for business success.

- A reach truck can optimize vertical space and improve efficiency.

- Layout must be optimized to accommodate the reach truck’s capabilities.

- Intelligent storage systems use data to make informed decisions about inventory management.

- Warehouse Management Software (WMS) acts as the central nervous system of a warehouse, providing analytics for better decision-making.

When you think about the backbone of your business, your warehouse might not always be the first thing that comes to mind. But in reality, it’s the silent hero, the foundation that keeps your operations running smoothly.

As the market grows more competitive, optimizing your warehouse storage isn’t just a nice-to-have; it’s a must-do to stay ahead. You’re about to discover some next-level strategies that can transform your storage from good to great, ensuring that every square inch of your warehouse is working hard for your business.

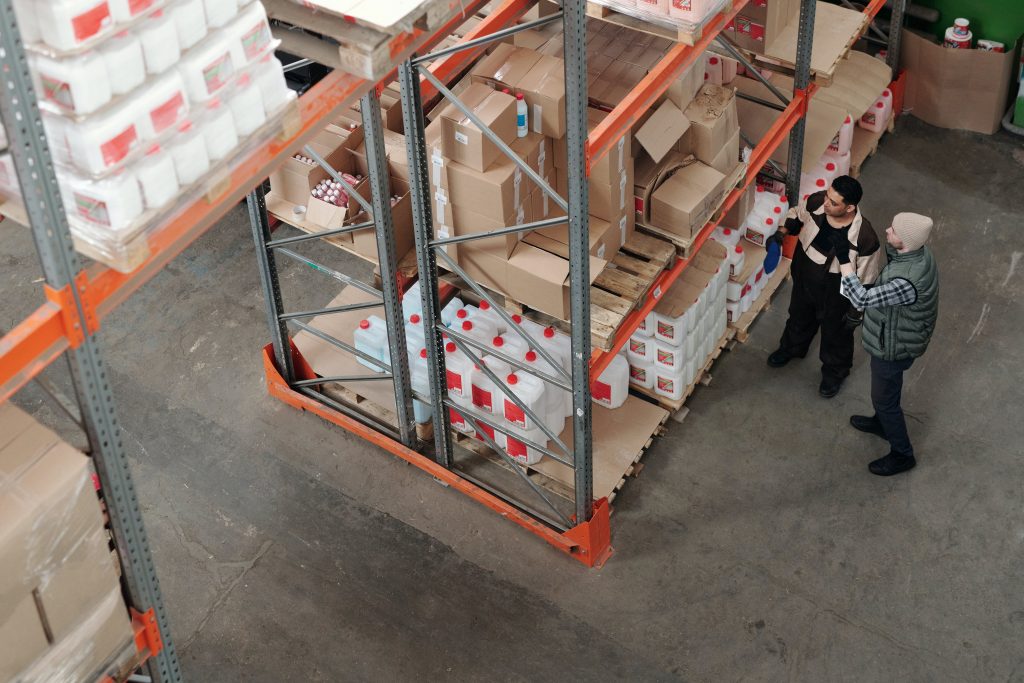

Enhancing Accessibility with a Reach Truck

Imagine a tool in your warehouse that not only helps you utilize every vertical space but also moves with such grace and efficiency that it elevates your entire operation. That’s where a reach truck comes in, a game-changer in warehouse storage.

Especially in places like Singapore, where the warehousing industry is rapidly advancing, the ability to go higher and work smarter is critical. A reach truck allows you to do just that, literally and figuratively reaching new heights.

Optimizing Layout for Reach Truck Maneuverability

When optimizing your warehouse layout, viewing it as a puzzle where each element needs to fit seamlessly for peak efficiency is crucial. In this puzzle, the reach truck, especially those utilized in Singapore, plays a key role. Think of your aisles as a meticulously choreographed dance floor tailored to accommodate the movements of your reach truck in Singapore.

This involves considering the truck’s turning radius and reach height and ensuring that each aisle is spacious and unobstructed for its smooth operation. Tailoring your warehouse design to enhance the capabilities of a reach truck in Singapore is not just a smart move; it’s a necessity to maintain a competitive edge.

Implementing Smart Storage Systems

Now, let’s talk about intelligence, not the kind you find in books, but the kind that transforms your warehouse into a powerhouse of efficiency. Intelligent storage systems are the brain behind the brawn, giving you the data and insights to make informed decisions about your inventory.

The Shift to Data-Driven Storage Solutions

In the digital age, data is king, and in the warehousing world, it’s no different. A smart storage system takes the guesswork out of inventory management. It tells you what you have, what you need, and what you can do without. For a bustling hub, where efficiency is not just a goal but a necessity, leveraging data-driven solutions can be the difference between thriving and just surviving.

Integrating Warehouse Management Software

In the heart of your warehouse’s transformation lies a powerful tool: Warehouse Management Software (WMS). Think of it as the central nervous system that keeps everything running smoothly.

With WMS, you’re not just tracking inventory; you’re unlocking a world of analytics that helps you predict, plan, and perform at levels you never thought possible. In this dynamic market, a WMS can differentiate between reacting to the trends and setting them.

Adopting Scalable Storage Solutions

Growth is the goal of any business, but with growth comes the need for adaptability in your storage solutions. Scalable storage solutions are like building blocks, ready to be rearranged to meet the demands of your ever-evolving inventory. In this industry, where business growth can be as rapid as the city’s skyline changes, having a storage system that grows with you is not just an advantage; it’s a necessity.

Flexible Racking for Dynamic Inventory Needs

Your inventory isn’t static, and neither should your racking be. Flexible racking systems are designed to adjust as your storage needs change. Whether you’re dealing with seasonal surges or a sudden influx of new products, your warehouse has to keep up.

Economic shifts can happen in a blink; flexibility in your storage setup means you’re always ready for what’s next, ensuring that your warehouse is as dynamic as the market itself.

Future-proofing with Modular Storage Components

The future is always around the corner, and future-proofing your warehouse means thinking ahead. Modular storage components allow you to expand, reduce, or reconfigure your storage space immediately. When innovation drives business, your warehouse will be ready to adapt to new technologies and processes that will shape the future of warehousing.

Wrapping Up

You’ve now seen how elevating your warehouse storage can lead to significant gains in efficiency and adaptability. By embracing the agility of a reach truck, the intelligence of intelligent storage systems, and the flexibility of scalable solutions, you’re not just keeping pace; you’re setting the pace.